Contact Form HP

We will get back to you as soon as possible.

Please try again later.

Contact Form HP

We will get back to you as soon as possible.

Please try again later.

New Paragraph

Injection Molding

For Research & Development And Training

In-House Molding Capabilities

- Small Scale Production

- Prototype Molding

- Up To 6 oz Shot Size

- Mold Size Capability: Max Of 20”

To learn more about our injection molding capabilities, contact:

Yiro Shimabukuro

Material Chemist

Polymer Injection Molding Services

Three injection molding machines are available at the Polymers Center for teaching, study, and product development purposes. Our main area of concentration is the molding of ASTM test specimens. We can also assist with short-run product requirements and in-depth tooling trials.

Two 55-ton presses and one 90-ton press are available in our lab. This consists of one hydraulic, one hybrid, and one all-electric machine. Each of these machines can process a variety of plastics, from commonplace to technical grades that need mold temperatures of up to 220°F. The Polymer Processing Laboratory also serves as a classroom for classes on injection molding.

To see how the Polymers Center can help, call Phil Shoemaker at

704-602-4100 or e-mail

contact-us@polymers-center.org.

Polymers Center Molds

Molds can either be supplied by the customer or by the Polymers Center, depending on the needs of our customers. If the objective is to test the material, molds are available at the Polymers Center.

Customers can select either our variable thickness 2"x3" plaque mold, which can be set between 0.02" and 0.20", or our ASTM family mold, which comprises a Tensile Bar, Flex Bar, and a Gardner Impact disk. For IZOD Impact testing, ASTM Flex bars may be cut down and notched. Customers can also bring their own mold to test whether it will generate sufficient parts.

Don't hesitate to get in touch with us for more information on the permitted mold dimensions.

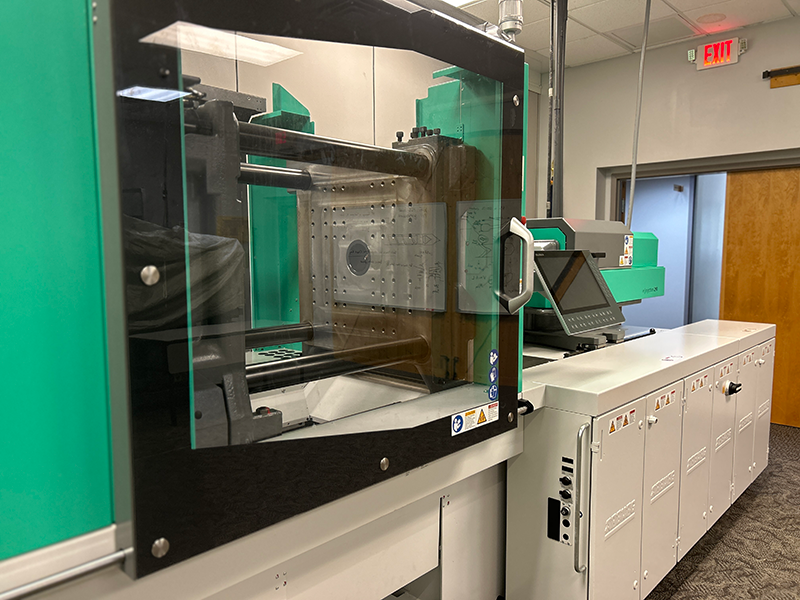

Injection Molding Equipment at the Polymers Center

We are thrilled to be a leading company of polymer development services in the Charlotte, NC area. Our facility has high-grade equipment and machinery to facilitate the creation of new plastic products. For any questions regarding the use of our machinery, please call us today, and we will be happy to assist!

ENGEL e-mac 85t (H3)

For an all-electric option, turn to the Engel e-mac 85t. It is highly efficient and extremely precise. Servo-electric drives are used to move the ENGEL e-mac in any direction. The trusted ENGEL CC300 control unit, which provides maximum flexibility on all ENGEL devices, is used by the ENGEL e-mac. You may also implement sophisticated injection molding applications with the ENGEL e-mac in a very effective and user-friendly manner. With acceleration on the injection axis of up to 22 m/s2, the ENGEL e-mac establishes a new standard of injection molding.

Shibaura Machine EC55SX III 55t

Plastics Machinery, LLC installed this All-Electric machine in 2019 with an Advantage TCU and a Sepro S5 Sprue Picker. The V70 controller has a 19" touchscreen that enables users to process outputs while simultaneously viewing configuration displays. Contamination is kept to a minimum because of its simple construction and lack of hydraulic fluid. This machine works quietly, making it perfect for training and for anyone new to injection molding practices.

Arburg Allrounder 520 A

German family-owned company Arburg is one of the world's leading manufacturers of plastic processing machines. Its product portfolio encompasses Allrounder injection molding machines with clamping forces of between 125 and 6,500 kN, the freeformer for industrial additive manufacturing and robotic systems, customer and industry-specific turnkey solutions and further peripheral equipment.