Contact Form HP

We will get back to you as soon as possible.

Please try again later.

Contact Form HP

We will get back to you as soon as possible.

Please try again later.

New Paragraph

Injection Molding

For Research & Development And Training

In-House Molding Capabilities

- Small Scale Production

- Prototype Molding

- Up To 6 oz Shot Size

- Mold Size Capability: Max Of 20”

Polymer Injection Molding Services

Two injection molding machines are available at the Polymers Center for teaching, study, and product development purposes. We can assist with short-run product requirements and in-depth tooling trials.

One 50-ton presses and one 165 ton press are available in our lab. The Polymer Processing Laboratory also serves as a classroom for classes on injection molding.

To see how the Polymers Center can help, call Yiro Shimabukuro at

704-602-4117 or e-mail

contact-us@polymers-center.org.

Polymers Center Molds

Molds can either be supplied by the customer or by the Polymers Center, depending on the needs of our customers. If the objective is to test the material, molds are available at the Polymers Center.

- Variable thickness 2"x3" plaque mold (0.02" to 0.20")

- ASTM family mold (D790, D638, D256, D5420)

- ISO family mold (527, 178/179, 180)

- Fan - gated 4"x6" rectangle

- Spiral flow

- Two - step chip mold

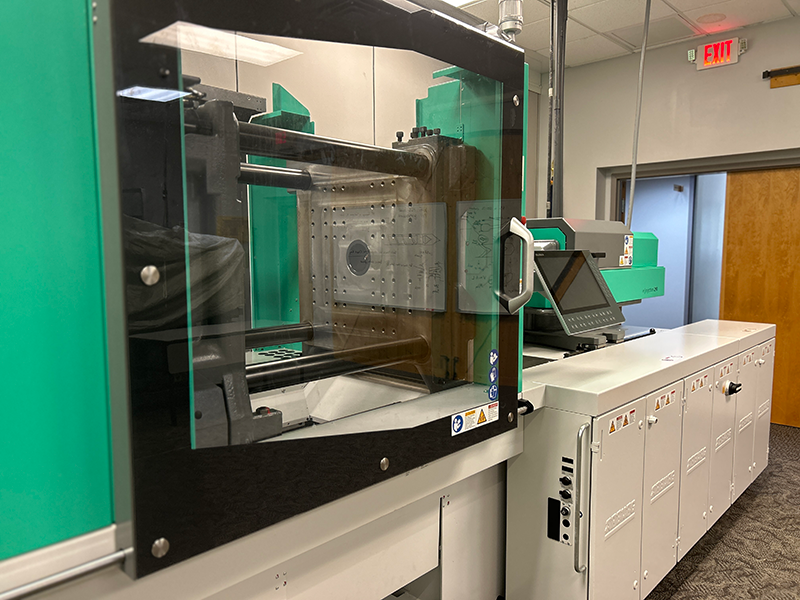

Injection Molding Equipment at the Polymers Center

We are thrilled to be a leading company of polymer development services in the Charlotte, NC area. Our facility has high-grade equipment and machinery to facilitate the creation of new plastic products. For any questions regarding the use of our machinery, please call us today, and we will be happy to assist!

Shibaura Machine EC55SX III 55t

Plastics Machinery, LLC installed this All-Electric machine in 2019 with an Advantage TCU and a Sepro S5 Sprue Picker. The V70 controller has a 19" touchscreen that enables users to process outputs while simultaneously viewing configuration displays. Contamination is kept to a minimum because of its simple construction and lack of hydraulic fluid. This machine works quietly, making it perfect for training and for anyone new to injection molding practices.

Arburg Allrounder 520 A

German family-owned company Arburg is one of the world's leading manufacturers of plastic processing machines. Its product portfolio encompasses Allrounder injection molding machines with clamping forces of between 125 and 6,500 kN, the freeformer for industrial additive manufacturing and robotic systems, customer and industry-specific turnkey solutions and further peripheral equipment.