From Sculpting to Printing—Technical Dead-Ends of the 3D Revolution

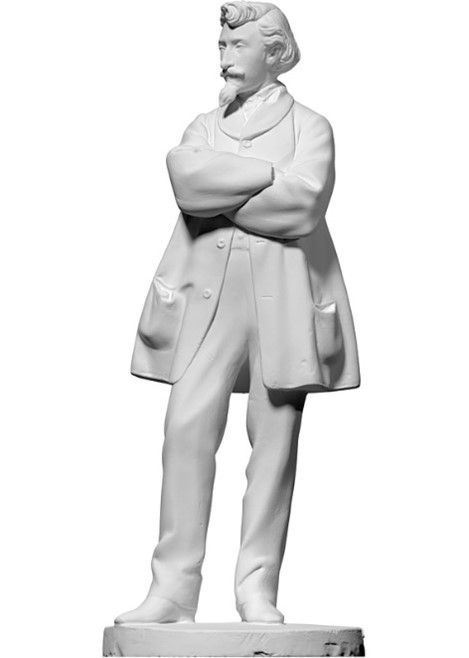

One might think that 3D printing started with Chuck Hall’s patent for stereolithography in 1986, but the roots of antecedent inventions extend remarkably deep into the past, starting with a French sculptor, François Willème. Sometime in the mid-1850s, while he was attending art school in Paris and making models for manufacturers of art bronzes, Willème learned of photography and realized its potential as an aid for making silhouettes. He set up an array of fifty cameras that enabled him to take simultaneous photos from a 360-degree circle that surrounded his object. Then, using the photographic silhouettes, he traced their outline with a pantograph onto a sheet of wood, cut out the silhouette then cut the sheet down the middle and ripped a 15-degree angle down its length. He then stacked the sheets together, each fifteen-degree wedge next to its neighbor, and cored out the center, forming a hollow cylinder. He could then use the prototype as a core, from which he could cast a rough sculpture. The coarse cutouts represented an extremely low-resolution representation of his subject, so it required a great deal of artistry to blend them together to form his model, but it cut the time required for such a process from months to days and corresponding lowered its price.

Willème considered himself the "inventeur de la photosculpture," and while he may not have utilized layers of uniform thicknesses, as we do today, and while he did “subtract” from his layers during their formation, he showed how to translate information into physical layers, then combine those layers to form a solid object.² So could we term Willème the father of additive manufacturing? The quick answer is no, not because his ideas were not original, nor because he did not compose his work out of successive layers, but because his invention ran into an evolutionary blind alley. By 1868 he was out of the photosculpture business and his process and those like it fell into disuse.

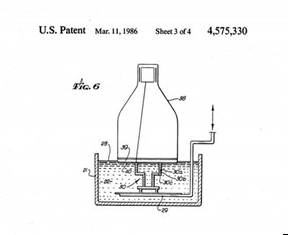

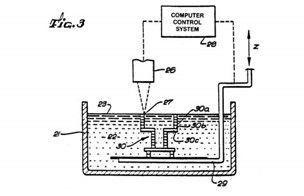

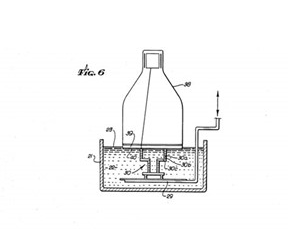

A little over a century later, in December 1972, Leone Isaure Marie Ciraud patented a method of manufacturing objects from a thermoplastic material that begins as “small particles” that he fused together using thermal radiation, “that has its focal point in a very small, practically point-like area” that agglomerates such particles in the shape of a volume that “depends on the movement given to the focal point of the thermal radiation.”³ Then, in 1981 Hideo Kodama also published a similar method of manufacturing of printing of solid models.⁴ Again, one might think that Ciraud’s and Kodama’s inventions would find immediate application, but it took another fourteen years after Ciraud’s idea to see practical success, and then only through a process that differed enough from his that it led to a new patent. As it turns out, Ciraud’s process and all other prior art were plagued by technical difficulties—a loss of resolution and intensity of the radiation at the intersections of the beams as they moved deeper into the photoreactive solutions, which made them unreliable. So, when Chuck Hall discovered how to master those problems, he patented an “Apparatus of production of three-dimensional objects by stereolithography,” US Patent No. US457330A. Utilizing stable, photoreactive polymers (a UV curable material) with stereolithography, he came up with the first 3D printer.

Chuck Hall’s drawing of stereolithography.⁵

Hall went on to form his company, 3D Systems, eventually growing it into an enterprise that will generate $540 million dollars in 2023 and one that has found applications in aerospace, automotive, health care, and pharmaceutical markets.⁶ (https://www.3dsystems.com/)

Chuck Hull’s patent references neither Willème nor Ciraud, nor should it, but that is the nature of technology—systems often originating from designs that are independent of antecedents in other fields. Simultaneous Invention, so named because it seems to occur regularly when the conditions are such that the invention would be obvious, bears a remarkable resemblance to convergent evolution, the development of similar structures in biological lineages that cannot be traced back to a common ancestor. Some, as in the biological realm, survive, but some large fraction do not. Willème’s techniques were duplicated and improved by others, but ultimately disappeared. Now, in a stunning example of art imitating an extinct art, they re-emerged in Columbus Ohio recently in the fourteen-foot sculptures designed by Matthew Mohr, AsWeAre, which replicated the 3D printing process to produce a rough model of a human head:

It may be a stretch to link Willème’s work of nearly two centuries ago to something so recent, and the layers may stack better now that they’re arranged horizontally, but those technical dead-ends sometimes remind us how ideas that were once barely possible are now commonplace—another feature of our technical worldview.

Footnotes:

¹ https://www.historyofinformation.com/detail.php?id=3876

² Robert A. Sobieszek, Sculpture as the Sum of Its Profiles: François Willème and Photosculpture in France, 1859-1868,” The Art Bulletin, Vol. 62, No. 4 (December 1980): pp. 617-630.

³ Leone Isaure Marie Ciraud, “Method and device for manufacturing any objects from any meltable material.” Patent No: DE2263777A1, December 27, 1972.

⁴ Hideo Kodama, “Automatic Method for Fabricating a Three Dimensional Plastic Model with Photo Hardening Polymer, Rev Sci Instrum, (1981): 1770-1773.

⁵ https://patents.google.com/patent/US4575330A/en

⁶ Alexandru Pirjan, Dana-Mihaela Petrosanu, „The Impact of 3D Printing on the Society and Economy,” Journal of Information Systems & Operations Management Vol. 7, No. 2, (December 2013): 360-370. For healthcare see, Yijie You, Yunlian Niu, Fengbing Sun, Sheng Huang, Peiyuan Ding, Xuhui Wang, Xin Zhang* and Jian Zhang, “Three-dimensional printing and 3D slicer powerful tools in understanding and treating neurosurgical diseases,” Frontiers in Surgery, October 14, 2022, 1-14.

CONTACT US TO LEARN MORE: 704-602-4100