Contact Form HP

We will get back to you as soon as possible.

Please try again later.

Contact Form HP

We will get back to you as soon as possible.

Please try again later.

The Polymers Center is proud to partner with a wide range of companies who help us achieve our mission to increase knowledge, provide technical support, and develop emerging technologies in the polymers industry. From injection molding training, to materials testing and robotics, our partners help us showcase the latest and greatest technology the industry has to offer.

Film Extrusion – Rheology and Processing

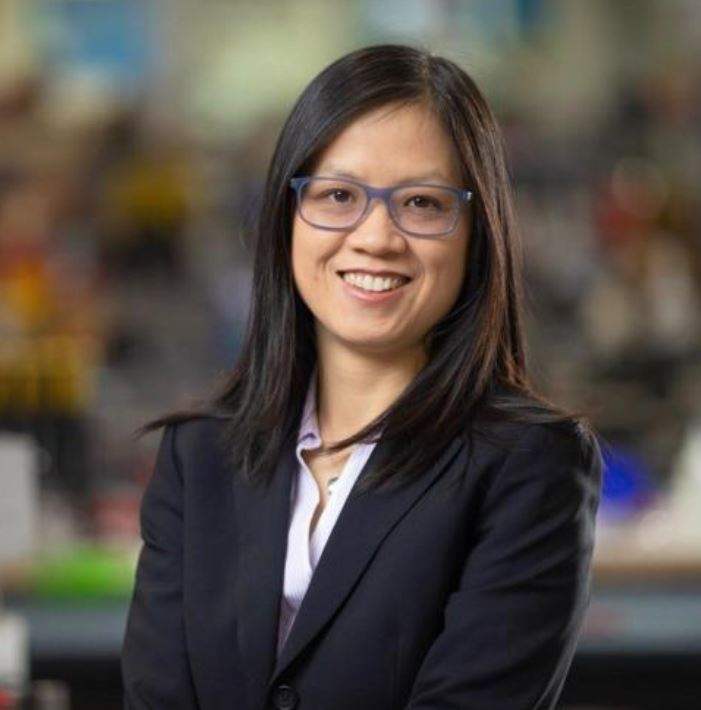

Film Extrusion – Rheology and Processing By Dr. Karen Xiao

Film Extrusion – Rheology and Processing’ is designed to provide one-day, hands-on instruction for those involved in single-screw extrusion processes, and especially on blown film. Stressing both the theory and practice of blown film, the course goes into the concepts of die design for both cast and blown film, and provides insight into the principal failure modes of such dies. Held at The Polymers Center, the class has access to our single screw machine and blown film line, as well as to the Material Science Lab.

Date: Tuesday, February 21, 2023

Time: 9:00am – 4:00pm

Where:

The Polymers Center

8900 Research Drive

Charlotte, NC 28262

Cost: $500

Class limited to twelve persons

Course Outline

Barrier Film Applications

- Shrink/non-shrink films

- Food and non-food packaging

Effect Of Polymer Rheology On Polymer Processing

- Polymer rheology fundamentals

- Rheology fundamentals

- Output, torque

- Viscous heat dissipation

- Melt temperature

- Example – using rheology to solve a real-world application

Extrusion Fundamentals

Part 1 – Extruders

- Extruder drives and motors

- Types of extruders

- Basic screw geometries

- Functional zones

- Example – feeding issue

Part 2 – Dies

- Types of dies design

- Both planar and annular dies

- Die design development

- Basic die design simulations

Winding Technology

- Surface winder

- Turret Winder

- Challenges in winding different films

- Thick film, thin film, tacky film, stiff film

Troubleshooting In Co-Extrusion

- Melt fracture

- Haze lines

- Curl

- Gels

- Polymer degradation

- Interfacial instability

Dr. Karen Xiao has been in the plastics industry for over 20 years. She is currently the Vice President of Technology for Macro Engineering and has overall responsibilities for Engineering, R&D, sales and marketing teams. Dr. Xiao also sits on the Board of Directors of Kwik Lok Corporation based in Yakima, Washington.

Previously Dr. Xiao was with Celgard LLC (an Asahi Kasei group company) in the battery separator film development area, and she also spent more than 10 years with Brampton Engineering in extrusion equipment design especially in the field of multilayer blown film. Dr. Xiao has been on the Board of Directors of the Extrusion Division at the Society of Plastics Engineers (SPE) since 2009. She was elected Fellow of the Society in 2016, and was the Extrusion Division Chair in 2015.

In her spare time, Dr. Xiao also likes to give back to the universities and is passionate about educating the next generation of engineers. She recently joined the Research Advisory Council at the University of Waterloo’s Faculty of Engineering, and the Industrial Advisory Council at the University of Wisconsin Madison’s Department of Polymer Engineering. Dr. Xiao has more than 60 publications in journals and conferences, 2 book chapters and 14 granted and pending patents in the field of extrusion. She holds a B.A.Sc. from the University of Toronto, and M.A.Sc. and a Ph.D. from the University of Waterloo all in Chemical Engineering.