PCE PLASTICS RECYCLING SYMPOSIUM 2025

Customers can compound a resin, injection mold ASTM test specimen, characterize their material in our testing lab, simulate an injection molding process and attend polymer education seminars all in one facility: The Polymers Center.

TESTING SERVICES

Do you need to know why your product isn't working, what a resin's physical characteristics are, or how to fix flow problems?

TRAINING COURSES

Are you wondering how to expand your knowledge in polymer materials, design, injection molding, and extrusion?

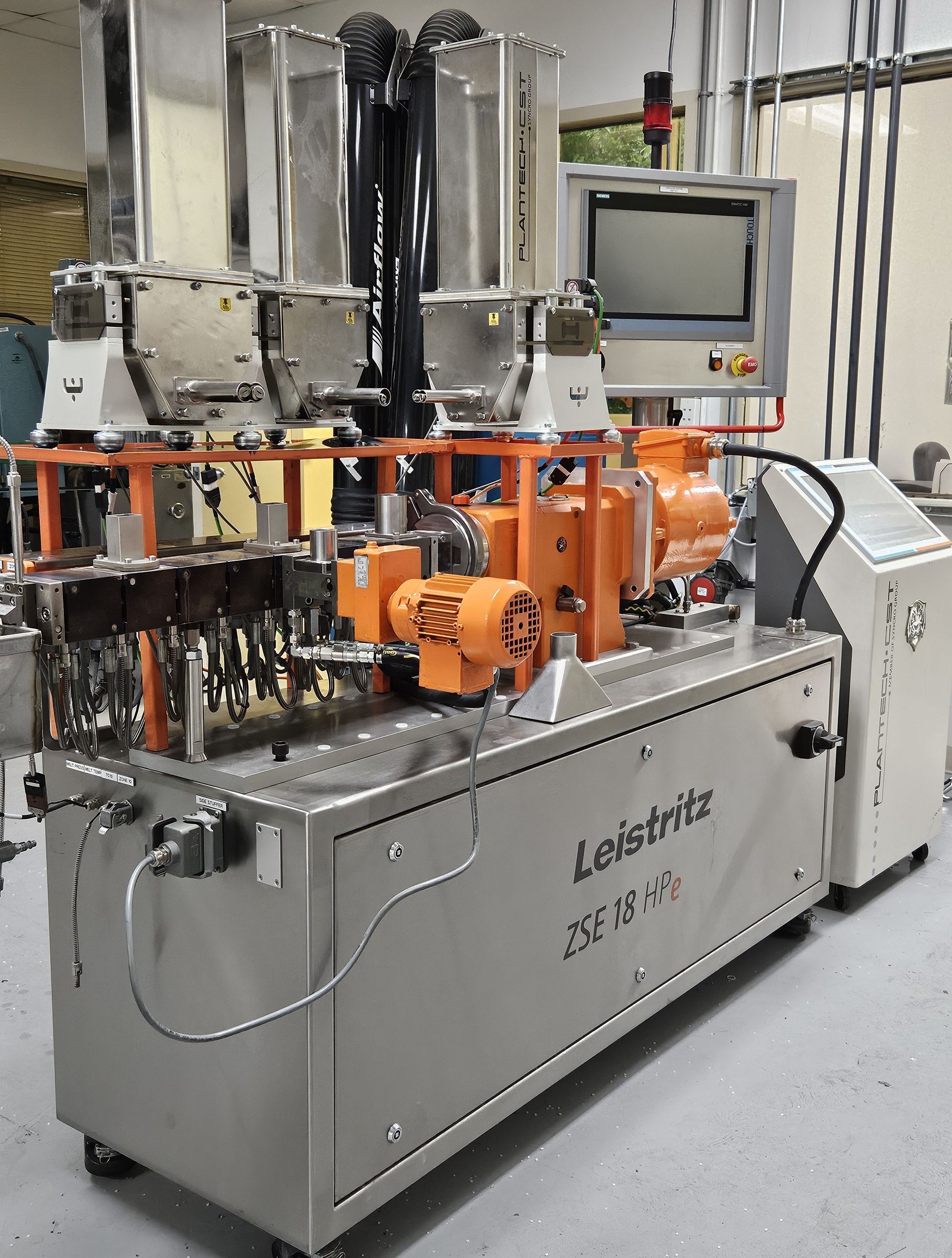

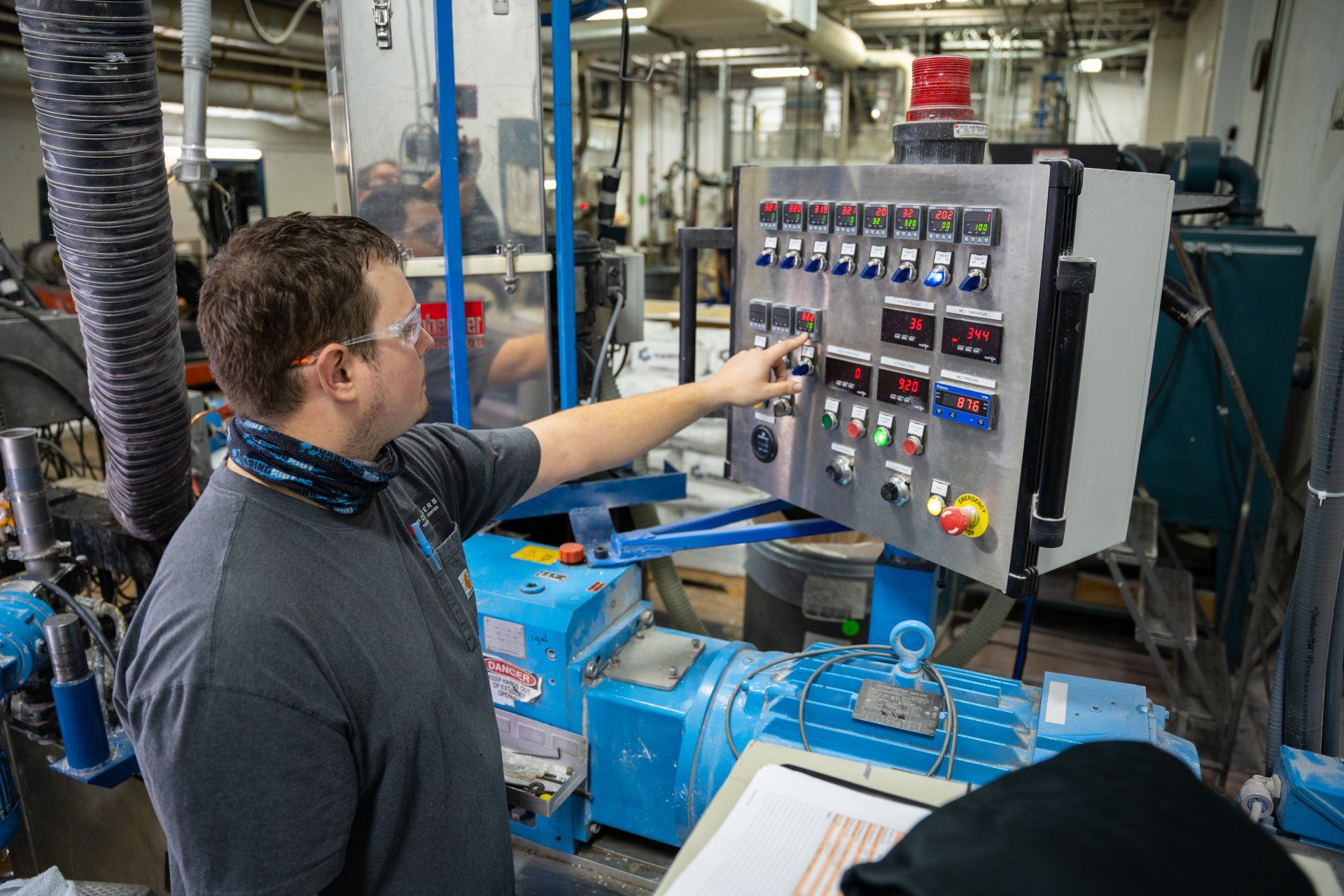

COMPOUNDING AND EXTRUSION

Do you need compounding and extrusion assistance?

We have what you need to develop your materials.

INJECTION MOLDING

Are you ready to evaluate injection molding problems?

Conduct your trials in our lab.

WHAT'S NEW AT THE POLYMERS CENTER

The Polymers Center here in North Carolina was established to further knowledge, offer technical assistance, and help businesses in the plastics industry. We provide the chance to work with experts in the field in a unique setting with the finest technology to enhance the performance of products.